Optima Weightech is an acknowledged Manufacturer, Supplier, Trader and Service Provider of superior quality Industrial Automation and Process Weighing Systems. We have reached this position thanks to our 4 main obsessions: Premium Quality, Reliability, Innovation and Exceptional Customer Service.

Weight Indicators

OPTIMA can supply range of weight indicators and controllers for every application from simple weight display to complex multi product batching control. Our range of indicators are rugged, high quality and cost effective.

Weight Transmitters

OPTIMA can supply range of weight indicators, transmitters and controllers for every application from simple weight display to complex multi product batching control.

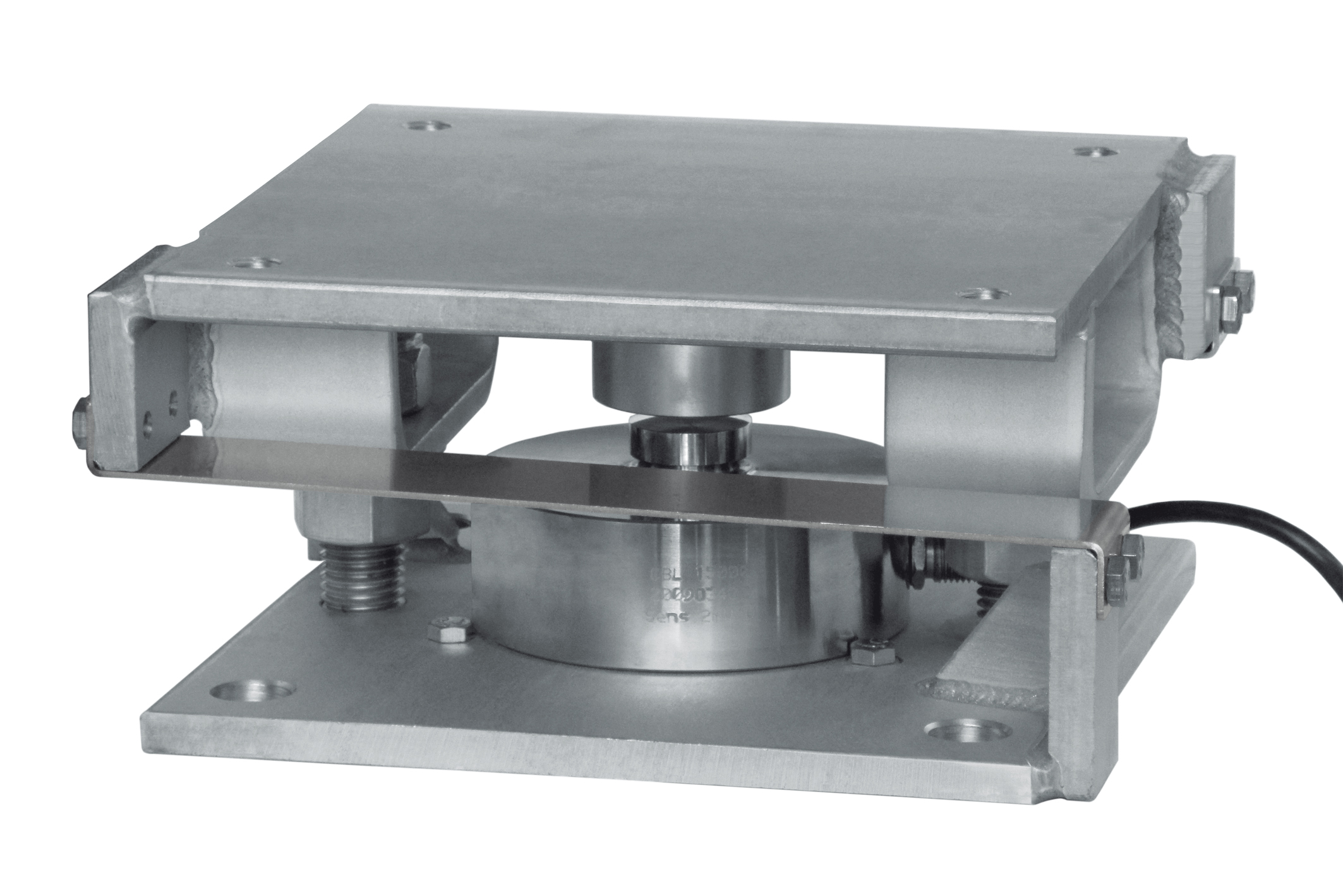

Load Cells and Mounting Kits

OPTIMA’s range of load cells are very accurate and rugged, constructed to last life time. We have always exceeded expectations of our customers in terms of quality and customer service.

Silo/tank/hopper Weighing Systems

Silo, tank, hopper, bin or bunker can be installed on top of load cells and the weight of the contents can be measured with a very high precision and easily communicated to external data systems such as PLC, HMI or SCADA.

We Have The Best Solution For Your Applications

Distributors of Trusted Brands

Application we work on

List of Major Applications we work on

What’s Our Customer Saying

Some possitive feedback about us that encourage

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

Juan Lee

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Stephen Philips

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

John Marrett

Let's Make Your Vision A Reality

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!