Contact Us Now

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

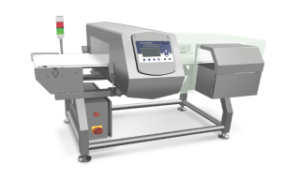

OPTIMA specialises in Food Metal Detector Systems. Over 26 years of experience in the field of instepctions systems makes us most realiable solution provider in the industry. We represent a world leading brand Techik in Australia.

Techik has installed over 12000 food metal detectors on production lines of every sector; from food to pharmaceutical, from personal care to pet food, companies large and small have recognised the quality of our metal detectors and count on them to safeguard their products and protect their brand.

Applications: Pharma, Food, Bakery, Meat & Poulty, Vegetables, Fruits, Costmetics, Waste Recycling etc. In short we have a food metal detector for any application.

It can detect all metal contaminants in packaged and non-packaged products, including ferrous metal (Fe), non-ferrous metal (Copper, Aluminum etc.) and Stainless Steel.

Techik food metal detectors are available with a degree of protection up to IP69K, can be integrated into checkweigher systems and installed within online systems for process analysis.

To provide complete turnkey solution for your need, OPTIMA can offer Miltihead Weighers, Linear Weighers, Packaging Machines, Checkweighers, Metal Detectors , X-Ray Inspection Systems and all accesories.

View our complete range of Food Metal Detector Systems in the following selection guide OR

Contact Us to talk with technical experts or to get a quick quotation now.

Conveyor Belt Metal Detector, Dimensions Up to 600mm, Up to 25 m/min

Metal detector for Biscuits with unique design of pneumatic retracting band type rejecter

Metal Detector for Pharmacy

Gravity Fall Metal detector

Metal Detector for Sauce

High Configuration Conevyor Metal Detector

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

The first DSP conveyor belt type metal detector , suitable for metal contaminants detection in various industries like: aquatic products, meat & poultry, salted products, pastry, nuts, vegetables, chemical raw materials, pharmacy, cosmetics, toys, etc.

Detecting all metal contaminants in packaged and non-packaged food, including ferrous metal (Fe), non-ferrous metals (Copper, Aluminum etc.) and stainless steel.

Special phase adjusting technology

High sensitivity with stable performance

Auto balance function

Touch screen

USB port

Dual-frequency

Customized rejecter system

Different surface treatment

Multi languages

Customization

Large memory capacity

Auto-learning product character

Finish auto-learning process very soon

| Model | IMD | |||

|---|---|---|---|---|

| Specifications | 4008,4012 4015,4018 | 5020,5025 5030,5035 | 6025,6030 | |

| Detection Width | 400mm | 500mm | 600mm | |

| Detection Height | 80mm,120mm 150mm,180mm | 200mm,250mm 300mm,350mm | 250mm 300mm | |

| Sensitivity | Fe | Φ0.5mm,Φ0.6mm Φ0.7mm,Φ0.8mm | Φ0.8mm,Φ1.0mm Φ1.2mm,Φ1.5mm | Φ1.2mm Φ1.5mm |

| SUS304 | Φ1.0mm,Φ1.2mm Φ1.5mm,Φ2.0mm | Φ2.0mm,Φ2.5mm Φ2.5mm,Φ3.0mm | Φ2.5mm Φ3.0mm | |

| Belt Width | 360mm | 460mm | 560mm | |

| Loading Capacity | 5kg~10kg | 20kg~50kg | 25kg~100kg | |

| Display Mode | LCD display panel (FDM touch screen optional) | LCD display panel (FDM touch screen optional) | LCD display panel (FDM touch screen optional) | |

| Operation Mode | Button input(Touch input optional) | Button input(Touch input optional) | Button input(Touch input optional) | |

| Product Storage Quantity | 52 kinds (100 kinds with touch screen) | 52 kinds (100 kinds with touch screen) | 52 kinds (100 kinds with touch screen) | |

| Conveyor Belt | Food Grade PU (chain conveyor optional) | Food Grade PU (chain conveyor optional) | Food Grade PU (chain conveyor optional) | |

| Belt Speed | Fixed 25m/min(Variable speed optional) | Fixed 25m/min(Variable speed optional) | Fixed 25m/min(Variable speed optional) | |

| Rejecter Mode | Alarm and belt stops(Rejecter optional) | Alarm and belt stops(Rejecter optional) | Alarm and belt stops(Rejecter optional) | |

| Power Supply | AC220V(Optional) | AC220V(Optional) | AC220V(Optional) | |

| Main Material | SUS304 | SUS304 | SUS304 | |

| Surface Treatment | Brushed SUS, Mirror polished, Sand blasted | Brushed SUS, Mirror polished, Sand blasted | Brushed SUS, Mirror polished, Sand blasted | |

| # | Enquiry | Enquiry | Enquiry |

.

.

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Biscuits type metal detector is with unique design of pneumatic retracting band type rejecter to prevent the product from being disordered. Biscuits type metal detector is widely used for different biscuits and sweets production line.

| Model | IMD-B | ||||

|---|---|---|---|---|---|

| Specifications | 60 | 80 | 100 | 120 | |

| Detection Width | 600mm | 800mm | 1000mm | 1200mm | |

| Detection Height | 50~80mm | ||||

| Sensitivity | Fe | Φ0.7mm | Φ0.8mm | Φ1.0mm | Φ1.2mm |

| SUS304 | Φ1.5mm | Φ1.5mm | Φ2.0mm | Φ2.5mm | |

| Belt Width | 560mm | 760mm | 960mm | 1160mm | |

| Conveyor Belt | Food grade PU | ||||

| Belt Speed | 15m/min (Variable speed optional) | ||||

| Rejecter Mode | Pneumatic retracting band type | ||||

| Power Supply | AC220V (Optional) | ||||

| Main Material | SUS304 | ||||

| # | Enquiry | Enquiry | Enquiry | Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Metal Detector for Tablets can reach high sensitivity and stability detection of ferrous metal (Fe), non-ferrous metals (Copper, Aluminum) and stainless steel. Metal Detector for Tablets is suitable to be installed after some pharmaceutical equipment like the tablet press machine, the capsule filling.

Metal Detector for Tablets can reach high sensitivity and stability detection of ferrous metal (Fe), non-ferrous metals (Copper, Aluminum) and stainless steel.

Metal Detector for Tablets is suitable to be installed after some pharmaceutical equipment like the tablet press machine, the capsule filling machine and the sieve machine.

| Model | IMD-M80 | IMD-M100 | IMD-M150 | |

|---|---|---|---|---|

| Detection Width | 72mm | 87mm | 137mm | |

| Detection Height | 17mm | 15mm | 25mm | |

| Sensitivity | Fe | Φ0.3-0.5mm | Φ0.3-0.5mm | Φ0.3-0.5mm |

| SUS304 | Φ0.6-0.8mm | Φ0.6-0.8mm | Φ0.6-0.8mm | |

| Display Mode | TFT touch screen | TFT touch screen | TFT touch screen | |

| Operation Mode | Touch input | Touch input | Touch input | |

| Product Storage Quantity | 100kinds | 100kinds | 100kinds | |

| Channel Material | Food grade plexiglass | Food grade plexiglass | Food grade plexiglass | |

| Rejecter Mode | Automatic rejection | Automatic rejection | Automatic rejection | |

| Power Supply | AC220V (Optional) | AC220V (Optional) | AC220V (Optional) | |

| Pressure Requirement | ≥0.5Mpa | ≥0.5Mpa | ≥0.5Mpa | |

| Main Material | SUS304(Product contact parts:SUS316) | SUS304(Product contact parts:SUS316) | SUS304(Product contact parts:SUS316) | |

| Enquiry | Enquiry | Enquiry | Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

With compact design and small occupied space, this type of metal detector is suitable for the detection of powder, granule or other forms of bulk products.

With compact design and small occupied space, this type of metal detector is suitable for the detection of powder, granule or other forms of bulk products.

| Model | IMD-P | ||||||

|---|---|---|---|---|---|---|---|

| Detection Diameter(mm) | Detection Capacity t/h2 | Rejecter Mode | Pressure Requirement | Power Supply | Main Material | Sensitivity1Φd (mm) | |

| Fe | SUS | ||||||

| 50 | 1 | Automatic flap rejecter | 0.5Mpa≥ | AC220V (Optional) | Stainless steel (SUS304) | 0.5 | 1.2 |

| 75 | 3 | 0.5 | 1.2 | ||||

| 100 | 5 | 0.7 | 1.5 | ||||

| 150 | 10 | 0.7 | 1.5 | ||||

| Enquiry | Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Easy to be integrated in existing sealed pipe system, this type of metal detector is suitable for the pump pressure fluid and semi-fluid product like sauce, liquid, etc.

Easy to be integrated in existing sealed pipe system, this type of metal detector is suitable for the pump pressure fluid and semi-fluid product like sauce, liquid, etc

| Model | IMD-L | ||||||

|---|---|---|---|---|---|---|---|

| Detection Diameter (mm) | Rejecter Mode | Pressure Requirement | Power Supply | Main Material | Inner Pipe Material | Sensitivity1Φd (mm) | |

| Fe | SUS | ||||||

| 50 | Automatic valve rejecter | ≥0.5Mpa | AC220V (Optional) | Stainless steel (SUS304) | Food grade Teflon tube | 0.5 | 1.2 |

| 63 | 0.6 | 1.5 | |||||

| 80 | 0.7 | 1.5 | |||||

| # | Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Frequency-selecting function, two frequencies can be chosen to match different products

Dual-detection system ensures Fe and Sus achieve its best sensitivity

Auto-balance function ensures stable detection

| Model | IMD-H | |||

|---|---|---|---|---|

| Specifications | 4008,4012 4015,4018 | 5020,5025 5030,5035 | 6,02,56,030 | |

| Detection Width | 400mm | 500mm | 600mm | |

| Detection Height | 80mm,120mm 150mm,180mm | 200mm,250mm 300mm,350mm | 250mm 300mm | |

| Sensitivity | Fe | Φ0.5mm,Φ0.6mm Φ0.7mm,Φ0.8mm | Φ0.8mm,Φ1.0mm Φ1.2mm,Φ1.5mm | Φ1.2mm Φ1.5mm |

| SUS304 | Φ0.9mm,Φ1.2mm Φ1.5mm,Φ2.0mm | Φ2.0mm,Φ2.5mm Φ2.5mm,Φ3.0mm | Φ2.5mm Φ3.0mm | |

| Belt Width | 360mm | 460mm | 560mm | |

| Loading Capacity | ≤10kg | ≤50kg | ≤100kg | |

| Display Mode | Touch screen | |||

| Operation Mode | Touch input | |||

| Product Storage Quantity | 100 kinds | |||

| Frequency | Dual-frequency | |||

| Checking Channel | Double channel checking | |||

| Belt Speed | Variable speed | |||

| Rejecter Mode | Alarm and belt stops (Rejecter optional) | |||

| IP Level | IP54/IP65 | |||

| Mechanical Design | Round frame, easy wash | |||

| Surface Treatment | Brushed stainless steel, Sand blasted | |||

| # | Enquiry | Enquiry | Enquiry |

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!