Contact Us Now

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

OPTIMA can supply range of weight indicators, transmitters and controllers for every application from simple weight display to complex multi product batching control. Our range of weight transmitters are rugged, high quality and cost effective. They are also available for harsh environments with IP68 and IP69K protection class. Weight Transmitters can be installed on panel, din rail according to your application. IECEx approved version for harzardous area application zones 0,1,2 for gas and 20,21,22 for dust are optionally available. Weight Transmitters are available with various communication options like 4-20mA analog output, RS232/485, Profibus DP, DeviceNet, CANopen, Profinet IO, Modbus/TCP, Ethernet/IP, Ethernet TCP/IP for remote management. Our weight transmitters have international approvals such as OIML and NMI Approval for Australia and New Zealand.

You can be assured of rugged build quality, reliability and ease of use.

To create a complete weighing system Optima have extentive range of Load Cells, Mounting Kits, Intellegent Junction Boxes, Weighing Assemblies, Weight Transmitters and accessories.

View our complete range of Weight Transmitters in the following selection guide OR

Contact Us to talk with technical experts or to get a quick quotation now.

Download our catalogues or read Applications.

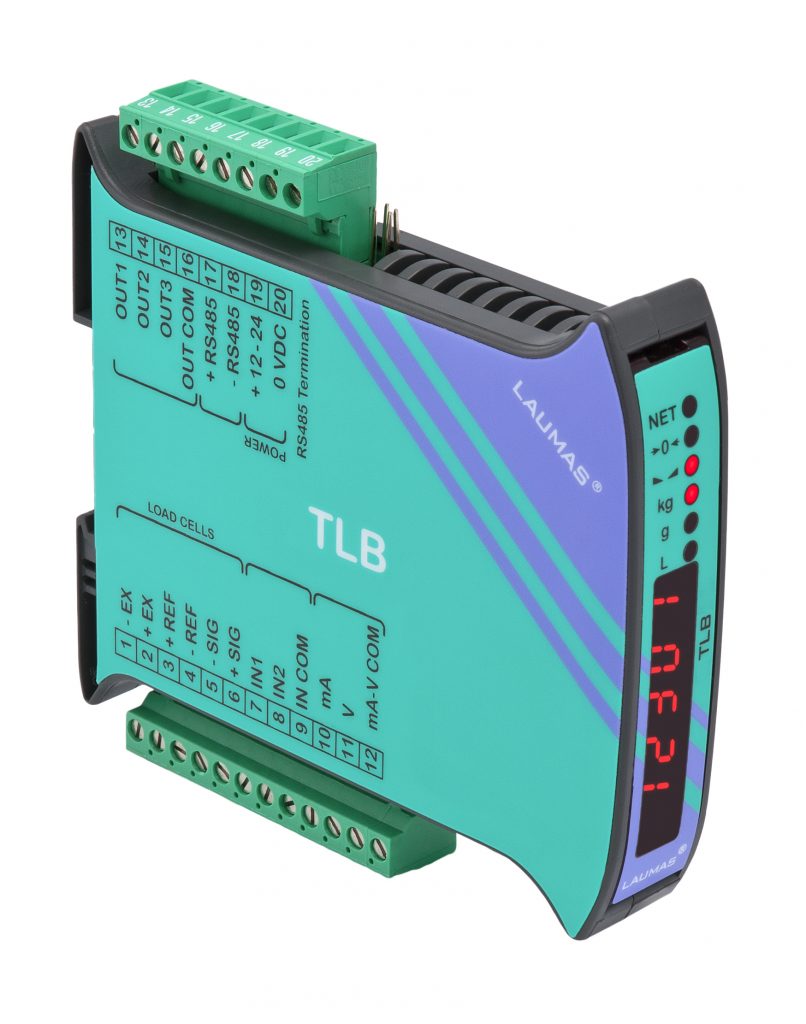

Digital/Analog Weight Transmitters, 1 Load Cell Input

Digital/Analog Weight Transmitters, 4 Independent Load Cell Inputs

Digital/Analog Weight Transmitters, 8 Independent Load Cell Inputs

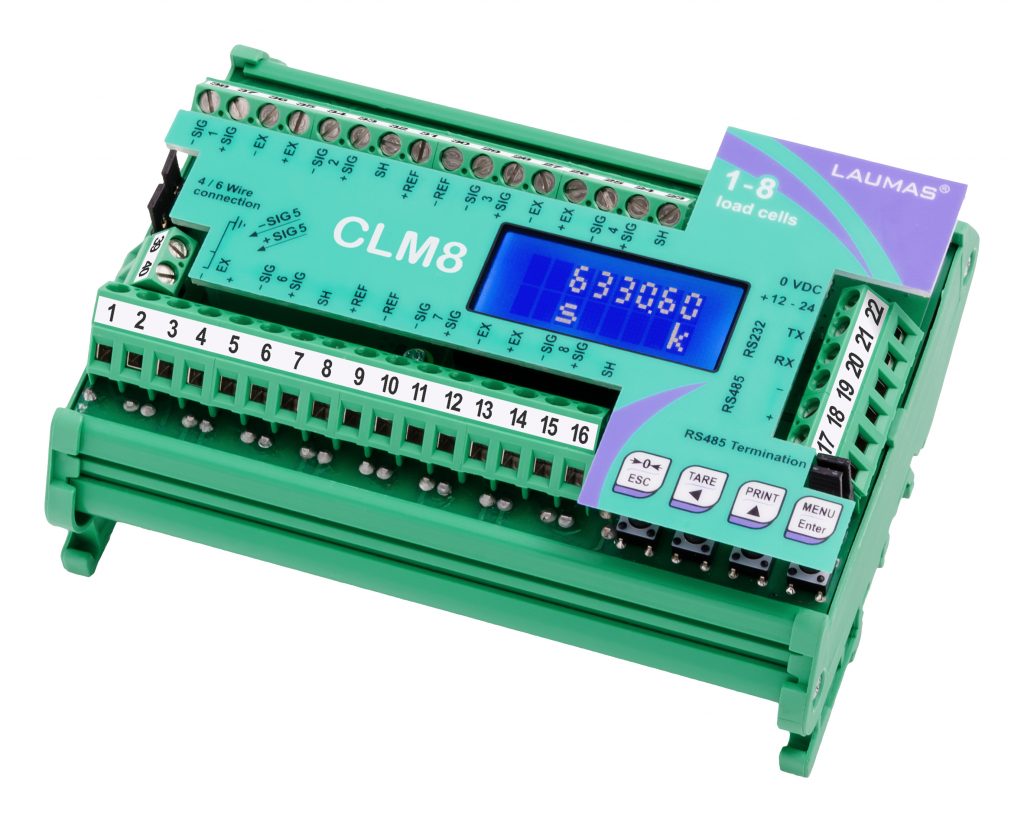

Intelligent Junction Box/ Weight Transmitters, 8 Independent Load Cell Inputs

Digital/Analog Weight Transmitters with WiFi, 1 Load Cell Input

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

TLB_EN  |

TLB_manual_EN  |

TLB_protocols_manual_EN  |

Electronic_instrumentation_catalog_EN (1)  |

Electronic_instrumentation_condensed_catalog_EN (1)  |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

TLB4_EN  |

TLB4_manual_EN  |

TLB4_protocols_manual_EN  |

Electronic_instrumentation_catalog_EN (1)  |

Electronic_instrumentation_condensed_catalog_EN (1)  |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

TLM8_EN  |

TLM8_manual_EN  |

TLM8_protocols_manual_EN  |

Electronic_instrumentation_catalog_EN (1)  |

Electronic_instrumentation_condensed_catalog_EN (1)  |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

CLM8_EN  |

Electronic_instrumentation_catalog_EN (1)  |

Electronic_instrumentation_condensed_catalog_EN (1)  |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

TLKWF_EN  |

TLKWF_manual_EN  |

TLK_TLKWF_protocols_manual_EN  |

Electronic_instrumentation_catalog_EN (1)  |

Electronic_instrumentation_condensed_catalog_EN (1)  |

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!