Contact Us Now

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

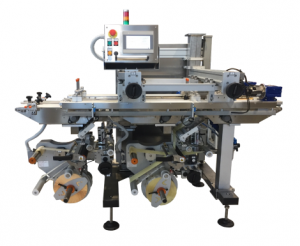

MODULAR structure “open frame” with an eye on technology.

The MODULAR series of automatic labelling systems represents the highest technical level range developed by LABELPACK in Italy in recent years. Designed and realized with modular standards built on a unique structure that better addresses the various needs of the market, MODULAR is a concrete answer to the needs of the cosmetics industry, pharmacies, and auto-labelling.

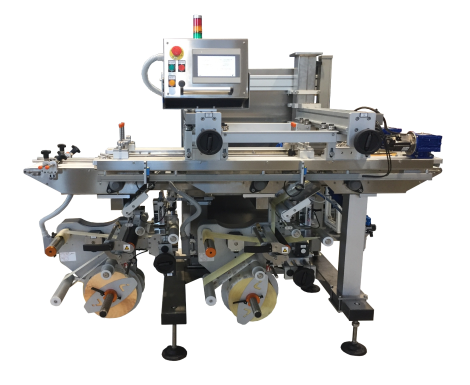

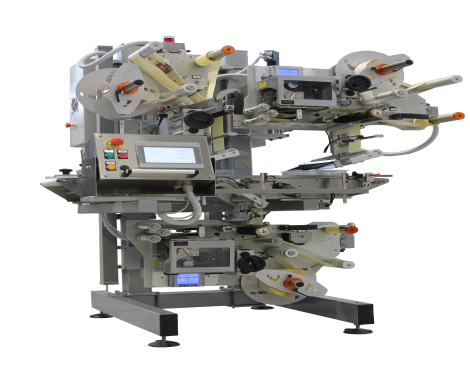

The automated labelling system MODULAR offers a number of customization options. The standard configuration of the MODULAR system includes central electronic control by PLC, touch screen control panel, electronic synchronization of all speeds, and fast adjustment by numerical position display.

An innovative solution for labelling flacon, vials, syringes, and other pharmaceutical products.

Flexibility, quick adjustment, precise application, high reliability, and typical “balcony” construction are the main features of the labelling system for cylindrical, conical bottles and cosmetic tubes. A labelling system with self-adhesive labels on the bottom of perfume bottles. Integrated solution for top and bottom application to cream jars, cans, and other flat products.

Flexible, versatile, and economical labelling system for the food and beverage industry. Suitable for labelling cans, jars, cream cheese, yogurt, dairy containers, glass or plastic bottles with one or more labels.

Solution for the labeling of components in the automobile industry: batteries and accumulators, crystals and body components, mechanical and electronic components.

Contact Us to talk with technical experts or to get a quick quotation now.

An automatic labeling system capable of applying a label to the bottom of bottles, glass or plastic jars and other cylindrical or rectangular containers with a Max. speed of upto 10,000 p/h and Max. label width of 140-250mm.

Labeling system for application of labels on bottom of food trays, high performance with double labeling module and non-stop function with a Max. speed of upto 10,000 p/h and Max. label width of 140-250mm.

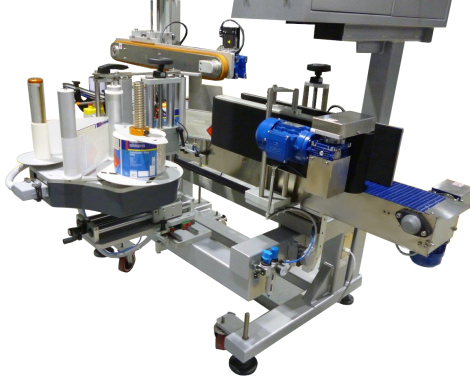

An automatic labelling system able to apply a wrap-around label and a bottom label onto nail polish bottles with a Max. speed of upto 3,000 p/h.

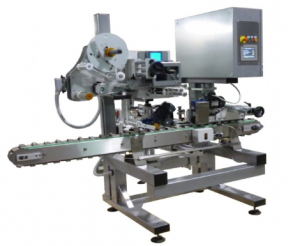

The automatic labeling system for the application of two labels, front and back, on bottles, cans, jars and other products of rectangular, oval or cylindrical shape for large productions. Max. speed of upto 10,000 p/h

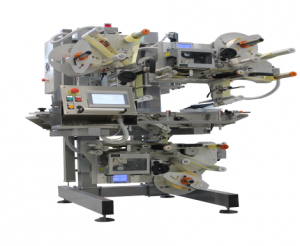

Designed to apply two "Tamper Evident" labels onto the opposite side of a pharmaceutical boxes. Max. speed of upto 10,000 p/h.

The labelling system to apply two opposite labels on the conical cups body at speeds of 150 ppm.

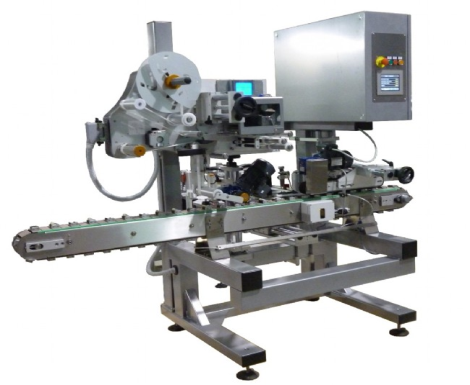

The labelling system equipped with a station for applying a label on the side of square, rectangular and oval containers, or with a wrap-around label on cylindrical containers.

Labeling system for the application of multiple labels on food trays with variable data printing in line.

Labelling solution for top & bottom application onto glass or plastic jars, trays, boxes and various cylindrical or rectangular products.

Labelling machine for top & bottom application onto trays, boxes, flow-pack, pillow bags, shrink package.

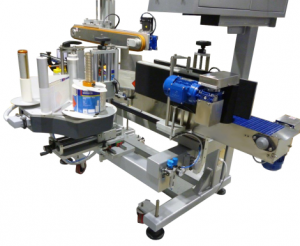

Labelling systems suitable for applying wrap around labels onto: flacons, jars, cans, glass or plastric bootles and onto various cylindrical prducts.

Automatic labeling system for unstable cosmetic containers for Mascara, Lip-gloss and Lipsticks.

Labeling system designed for the application onto vials, small cylindrical bottles and unstable cylindrical products.

Automatic labelling system suitable for application of wrap around label onto flacons, jars, cans, glass or plastic bottles and various cylindrical products.

An automatic labelling system suitable for application of two labels, front & back, onto flacons, jars, cans, glass or plastic bottles and various cylindrical products.

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

It is an automatic labeling system capable of applying a label to the bottom of bottles, glass or plastic jars and other cylindrical or rectangular containers. Particularly suitable for the cosmetic and perfumery industry as well as for the food industry.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Labeling system for application of labels on bottom of food trays, high performance with double labeling module and non-stop function.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

An automatic labelling system able to apply a wrap-around label and a bottom label onto nail polish bottles and can work up to 3000 pieces per hour applying a round label on the bottom and a body label with automatic orientation reffering to the pre-printed logo onto the cap. The body label is personalized on-line with the printing of barcodes and variable data through a thermal transfer printing module.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

This is the automatic labeling system for the application of two labels, front and back, on bottles, cans, jars and other products of rectangular, oval or cylindrical shape for large productions. The four labeling units with No-Stop function allow you to change labels without stopping the line. Particularly suitable for the cosmetics, chemical and food industry thanks to its precision, reliability and simplicity of regulation.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

This labelling system has been designed to apply two “Tamper Evident” labels onto the opposite side of a pharmaceutical boxes.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

This labelling system is capable of applying two opposite labels on the conical cups body at speeds of 150 ppm.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

The system can be configured with a product spacer device with motorized parallel belts and with an aligner device with motorized chains that guarantees correct alignment of elliptical-based bottles. A LABELX labeling machine provides for the application of the label and can integrate a thermal transfer printing unit for managing the printing of variable data. System control is entrusted to a PLC with touch screen operator panel equipped with access for remote assistance management. Ind. 4.0 ready.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Multiple labeling solution for the application on food trays with variable data printing in line.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

This is the right solution for top & bottom application onto glass or plastic jars, trays, boxes and various cylindrical or rectangular products. Particularly indicated for the cosmetic, perfumery and food industries.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

This is the right solution for top & bottom application onto trays, boxes, flow-pack, pillow bags, shrink package. Particularly indicated for food industries.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

The high perfomence automatic labelling systems suitable for applying wrap around labels onto: flacons, jars, cans, glass or plastric bootles and onto various cylindrical prducts.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Automatic labeling system for unstable cosmetic containers for Mascara, Lip-gloss and Lipsticks. The system is designed for the application of multiple labels on a container for cosmetics with positions predetermined by the presence of the print on it. The product is suitably oriented by a rotation device equipped with a print reading camera on the container. In the first station the barcode label is applied, then the “Water-Proof” stamp is applied. In the third station, the side stamp is applied on the cap / bottom of the product and lastly a fourth transparent seal of guarantee label is applied.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

The system is endowed with a second labelling unit that apply a small sticker onto the cup. Sectors of application: vials for diagnostic products, pharmaceutical and cosmetic vials , lipstick and other unstable products.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

This the automatic labelling system suitable for application of wrap around label onto flacons, jars, cans, glass or plastic bottles and various cylindrical products. This system is equipped with a three rolls automatic rotating device which allow to apply label onto instable product or with automatic orentation of the label position.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

This the automatic labelling system suitable for application of two labels, front & back, onto flacons, jars, cans, glass or plastic bottles and various cylindrical products. This system is equipped with a three rollers automatic rotating device which allow to apply label onto instable product or with automatic orentation of the two labels position.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!