Contact Us Now

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

OPTIMA specialises in Volumetric Dosing/Filling Machines. The machine works with flowmeter and gear pump combination. The flowmeter base dosing machines are very popular for filing liquid products accurately.

Over 26 years of experience in the field of liquid filling machines makes us most realiable solution provider in the industry.

Product Types: For any liquid like juice, beer, olive oil, chemical, soap, paste etc.

The Volumetric Dosing Fillers are available in wide range of models and configurations to be able to weigh all kinds of liquid products. The structure is completely made exclusively of stainless steel. All parts in contact with the product can be quickly and easily disassembled for thorough cleaning.

Our Volumetric Dosing Fillers are available with manual, semi automatic or fully automatic.

As every application is different in this sector we recommend you to contact us to discuss your requirements and we will visit you to understand your requirements.

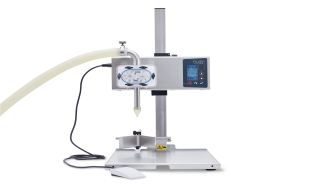

OPTIMA is a professional self-learning dosing machine suitable for dosing food or industrial products, filtered liquid or semi-dense liquid,

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

OPTIMA is a professional self-learning dosing machine suitable for dosing food or industrial products, filtered liquid or semi-dense liquid, capable of meeting multiple needs in terms of container capacity, filling speed, accuracy of the filling level, type of containers used. The possibilities of use are severals: food liquids (OIL, WINE, JUICES), cosmetics (ESSENTIAL OILS), CLEANING LIQUIDS (also alcohol-based). The minimum capacity is 8 milliliters, while the maximum capacity has only a limit in the size of the container to be used compatible with the size of the machinery. It is possible to fill glass, aluminum, PET bottles, flexible containers.

| Model | Containers production 5 lt/h | Dimension | Capacity | Engine (Kw) | Weight kg | # |

|---|---|---|---|---|---|---|

| 9020 | 380 | 600x600x1600 mm | 5 – 1000 | 1,2 monophase | 110 | Enquiry |

SIMPLICITY: filling is quick and completely automatic: the operator must select the container to be filled and start the machinery, deciding whether to perform multiple filling cycles or only one cycle. The setting of the various formats to be filled takes place in a few seconds through the NEW function: it is the operator who decides the filling speed for each individual format, having the possibility of setting a double speed in cases where it is deemed appropriate. Furthermore, it is always possible to modify the set parameters by making minimum increases or decreases on the quantity dispensed (± 1ml).

OPERATION: the filler is equipped with a gear dosing pump built entirely in stainless steel, controlled by an electronic speed variator, and a control PLC with dedicated software. Through the multi-colored touch screen it is possible to access all the functions and settings of the machinery, displaying the various formulas set, the modifiable parameters and the new storage function. The pump used is self-priming and it is sufficient to connect it to the product storage tank to be able to start filling.

OTHER ADVANTAGES: AUTOMATIC operation with setting of only the pause time between one cycle and the next; start of the machine with remote push-button; luminous warning start of filling to avoid lack of container or unwanted starts; structure completely in AISI 304 stainless steel; height-adjustable bottle support surface; bottle centering device; total product discharge valve inside the circuit; no metric approval required.

DOSYPACK FILLING: the machine can be supplied in the version for filling and capping flexible containers like Dosypack. The installation of the bag is manual; filling is automatic with the dosage as indicated above; bags are capped with the appropriate pneumatic capper. The operator manages the two filling and capping phases through the appropriate lever.

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Fillogy Flowable M filling machine is suitable to all free thick liquids and viscous products.

Data Sheet Fillogy Flowable M

|

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Fillogy Flowable L is machine for the dosed filling of non flowable and viscous products.

Machine for the dosed filling of non flowable and viscous products, e.g:

Main field of application: filling of container sizes from 50 to 500 g

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!