Dedicated Customer Teams For An Agile Services

Individually assess each application and Offer optimal

solutions!

Commercial & Industrial Projects!

Have any query, our customer support team excels in dealing with all your related queries.

We are one of the biggest weighting system supplier in Australia.

We are always ready to provide indepth technical advises

Our Service is highly rated in the industry.

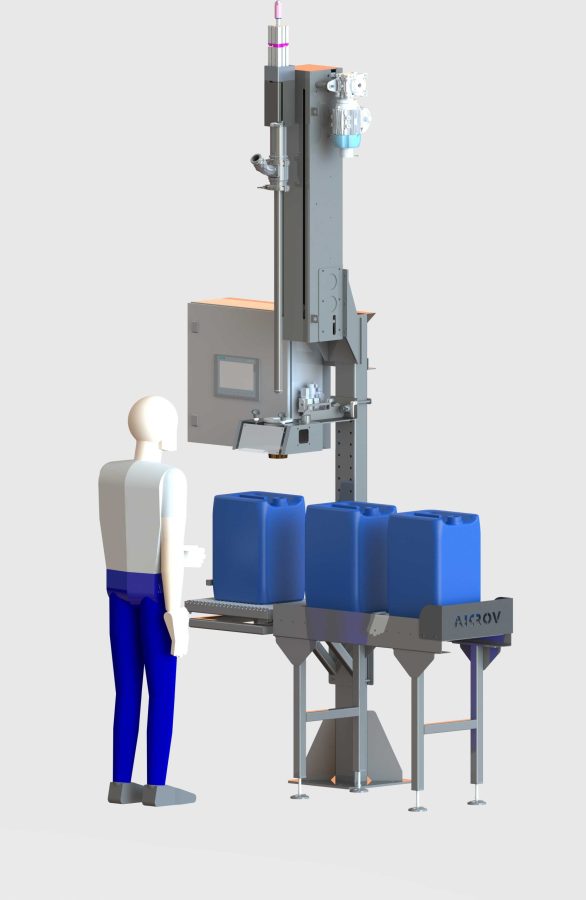

Optima Weightech is an acknowledged Manufacturer, Supplier, Trader and Service Provider of superior quality Packaging Machines, Inspection Systems and Weighing Components. Our assortment of products is known for its superior performance, precise output and high durability. These are used across various industries and laboratories for measuring the weights of various loads.

We are a group of experienced and qualified employees that understands your problem and provides suitable solutions.

Our products never ever fail to deliver the best results. We strive on making our products the best in terms of quality.

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"