Contact Us Now

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Optima specialises in Bulk Inline Weighers for free flowing and non free flowing proucts like grain, pulses, granules, malt, pellets, soya and diverse bruised grains available from Friedrich Electronic,Germany.

Our product range includes Verticle Pipe Weigher (Impact Weighers), Flow Controller, Batch Controller, Rotor Weigher.

To create a complete weighing system Optima also have extentive range of Silo Weighing Systems.

View our complete range of Bulk Inline Weighers in the following selection guide OR

Contact Us to talk with technical experts or to get a quick quotation now.

Download our catalogues or read Applications.

Verticle Pipe Weigher For Continuous Weighing Of Free Flowing Bulk Solids

Flow Controller FC3 For Continuous, gravimetric dosage of free flowing bulk solids

Batch Controller FC3 For Batch Dosing Of Free Flowing Bulk Solids

Rotor Weigher RC For Continuous weighing of poor flowing bulk solids

Automatic Dampening System For All Grain Types

Online Moisture Measuring System

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Applied products:

All free flowing products can be measured, e.g. grain, pulses, granules, malt, pellets, soya and diverse bruised grains.

The Vertical Pipe Weigher continuously weighs free bulk flow.

Continuous weighing of free flowing bulk solids

External electronic type FE128

Available for panel mounting (24 V DC) or inside wall housing (230 V AC), can be installed independent from the dosing unit, connection of max. 2 weighing units, with LCD-display and keypad, display of capacity and total weight, preselection function, output if kg-pulses and analogue output of capacity (0-10 V), graphic registration over 48h, 10 product-specific. calibrations possible, RS232-485-interface.

The bulk is slowed down by means of a falling brake. Then it is reaccelerated and fed into a pipe bend. The pipe bend is connected with a load cell. The measured force is proportional to the throughput.

Contact Us to talk with technical experts or to get a quick quotation now.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

The Vertical Pipe Weigher DCG is suited for the following applications:

.

.

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Applied products:

All free flowing products can be measured, e.g. grain, pulses, granules, malt, pellets, soya and diverse bruised grains.

Continuous, gravimetric dosage of free flowing bulk solids:

An electrically controlled flat slider is located in a steel housing. Under the flat slider there is a weighing sensor which measures the product flow rate. The user enters a desired flow capacity and starts dosage. The flat gate opens gradually and the product flows with increasing flow capacity over the weighing sensor. When reaching the desired flow capacity, movement stops.

Contact Us to talk with technical experts or to get a quick quotation now.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

The Flow Controller FC3 is suited for the following applications:

For operation of the Flow Controller FC3 full product stock at the inlet of the device is required.

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Applied products:

All free flowing products can be measured, e.g. grain, pulses, granules, malt, pellets, soya and diverse bruised grains

Batch dosing of free flowing bulk solids:

A pneumatic controlled flat gate is located in a steel housing. Under the flat gate there is a weighing sensor which measures the product flow rate. The user enters a desired batch amount and starts dosage, the flat gate opens and the product flows with maximum capacity over the baffle plate. When reaching the desired amount, the dosage is stopped.

Contact Us to talk with technical experts or to get a quick quotation now.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

The Batch Controller BC3 is suitable for the following applications:

For operation of the Batch Controller BC3 full product stock at the inlet of the device

is required.

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Applied products:

A large number of poor flowing products can be measured, e.g. flour, powder and bran.

Continuous weighing of poor flowing bulk solids Overview:

A horizontally aligned rotor is located inside the Rotor Weigher. It is driven at constant speed. The product is fed to the center of the rotor and accelerated to approx. 9 m/s. The occurring Coriolis force is gathered by a torsion spring and captured by a flux induction sensor. The system is completely proportional to the mass flow measurement. Material-specific characteristics such as flow characteristics or friction are not included in the measurement as errors.

Contact Us to talk with technical experts or to get a quick quotation now.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

The Rotor Weigher RC is suited for the following applications:

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

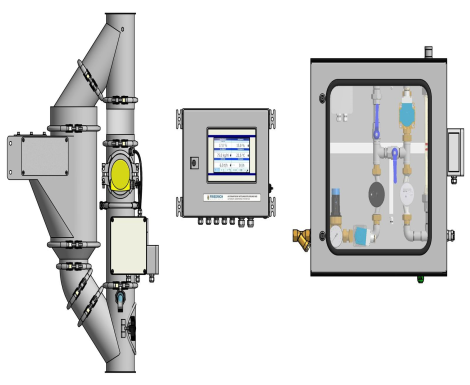

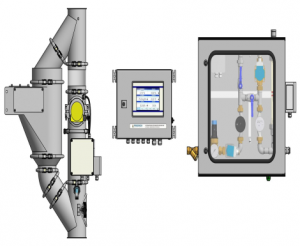

The NC 8 Automatic Dampening System continuously measures free product flow. The product moisture is measured in the bypass pipe.

By application of the Automatic Dampening System a mill can achieve optimal performance by maintaining its grain moisture at a constant level. The required water amount to be given into the grain – in order to achieve target moisture – is calculated of actual moisture and grain flow.

All free flowing grain types can be measured, e.g. wheat, spelt, rye, barley, oat, maize, pepper and malt.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Continuous monitoring of moisture content of free flowing bulk solids, grain and granules

The Online Moisture Measuring Unit MC is used for continuous monitoring of moisture contents of free-flowing bulk solids, in particular grain and granulates. A high frequency probe, centrally mounted in a measuring pipe, measures the relative permittivity and temperature of the bulk material passing the probe. These values are continuously processed by the evaluation unit in order to determine the moisture contents of the material; this is then displayed digitally.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

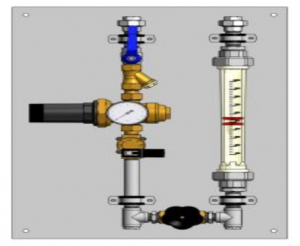

The water dosage unit is used to moisten grain manually. The dosing unit is connected to the drinking water pipe. Any water flow rate can be set. The water flow is initiated by actuating a solenoid valve.

The water dosage unit can be assembled at any place between water supply and intensive dampener.

For control of the solenoid valve a mains connection of 230 V / 1 A is required. It is recommendable to connect this valve to a capacitive proximity switch. This proximity switch must be assembled so that is switches when grain is running through the intensive dampener.

The correct water flow in l / h is set by the following calculation:

Grain flow in t/h x target % of water addition x 12

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!