Contact Us Now

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

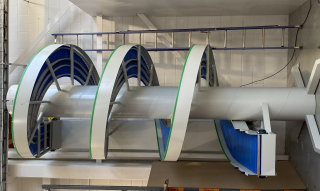

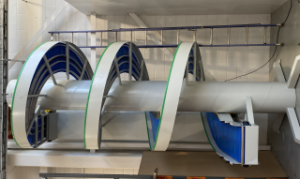

Spiral Conveyors, Up or Down, Slat Widths Up To 26 inches.

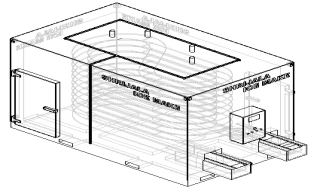

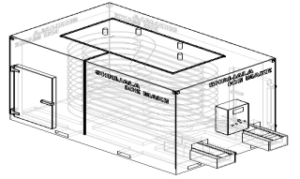

Spiral Freezer Conveyors, For Any Food Products Packed Or Loose

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Our Spiral Conveyors are of a modular design and are available in several standard versions to accommodate a broad range of loads and applications. These spirals can go up or down and be made revesible. All models can have extended in and out feed, making Spiral Lifts easy to fit in most layouts.

High Throughput: The standard load capacity is 30 Kgs per linear foot of conveyor for speeds up to 200 feet per minute.

Single Drive: The Spiral Conveyors need only one drive motor, even for units several stories tall. This equals to substantial savings in controls and system integrations.

Small Footprint: Spiral Conveyors have the smallest footprint available and therefore provide substanial space savings.

Overlapting Slats: The overlapting slats provide smooth efficient conveying surface suitable for a wide variety of loads and sizes. The slats are made up of fiberglass reinforced Polyamide and are available in widths of 4″, 6″, 8″, 12″, 16″, 20″ and 26″.

Ask Us A Question about our Spiral Conveyors

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

• Continuous inline food freezing

• Gentle, smooth handling of product

• Factory assembled and tested

• Stainless steel constructed

• Easy access to sanitation and maintenance

• Tailor made Solutions , Cost Effective

• Energy Saving Great Flexibility

• Standard Solutions

• Minimum Defrosting Requirements

• Longer Production Hours

• Small foot prints, Saving in processing floor space

Ask Us A Question about our Spiral Freezer Conveyors

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

Backery & Pastry, Containers/ Pots & Ready Meals, Dairy Products & Ice Creams, Meat, Poultry, Sauce & Liquids, Sea Food, Vegetables, Wheat & Grain Products.

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!