Contact Us Now

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

OPTIMA specialises in Pre Made Bag Packaging Machines. Over 26 years of experience in the field of packaging machinery makes us most realiable solution provider in the industry.

The new pre made bag packaging machine is with the latest technology and highest performance.

Product Types: Dry Food, Wet Food, Snacks, Granules, Sweets, Coffee, Bakery, Liquids, Powders, Meat, Hardware etc.

Bag Types: DOY Bags, Pillow Bag, Gusset Bags, Zipper Bags.

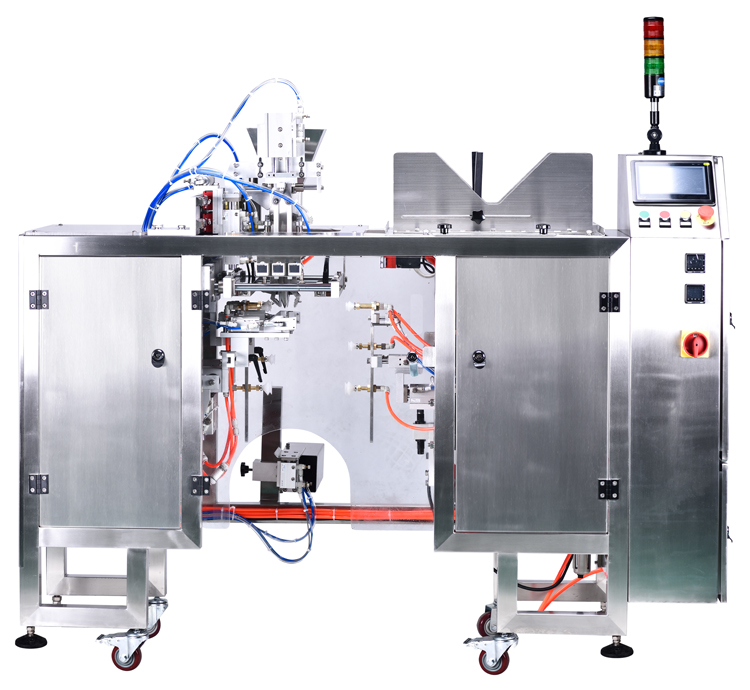

It is a simplified version pouch machine for various pre-made bags such as pillow bags, gusset bags, zipper bags etc. As a cost saving solution, it is an idea for a lot of application such as coffee, frozen foods, cookies, cereals, nuts, flower, candy etc. It can also be interfaced with other equipments for use with turnkey lines.

It can be equipped with different dispensers depending on the type of product to dispense: volumetric for granules, auger filler for dusts, piston or flow meter for liquid and doughy, linear and multihead weighers … etc.

As a complete solution provider, we have range of

As every application is different in this sector we recommend you to contact us to discuss your requirements and we will visit you to understand your requirements.

View our complete range of Pre Made Bags Packaging Machines in the following selection guide OR

Contact Us to talk with technical experts or to get a quick quotation now.

Premade Bag Packaging Machine, Up to 15 bags per minute

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

The OP-HP1 series premade bags packaging machine is ideal and economical solution for premade pouches.

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

It is a simplified version pouch machine for variety of bag styles, including 3 or 4 sided seal pillow pouches, stand up bags, gusseted pouches and quad seal bags etc. As a cost saving solution, it is an idea for a lot of application such as coffee, frozen foods, cookies, cereals, nuts, flower, candy etc. It can also be interfaced with other equipments for use with turnkey lines.

Stand up pouches make ideal containers for a variety of solid, liquid and powered foods as well as non- food items. Premade pouches are convenient as unlike form & seal technology, equipment change over time is not required when using pouches with the same size requirements but different graphics.

Food grade laminates help keep your food products fresher for longer and provide significant convenience if a zipper is included while also the ample surface area makes a perfect product branding providing visually appealing graphics.

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!