Contact Us Now

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

Silo, tank, hopper, bin or bunker can be installed on top of load cells and the weight of the contents can be measured with a very high precision and easily communicated to external data systems such as PLC, HMI or SCADA.

Typical materials that are stored in silos/tanks/hoppers:

A silo weighing system is consists of three or four load cells, each with a weighing module, an intellegent junction box and a weight indicator or transmitter. The mounting kit (weighing module) ensures that the correct amount of force is applied to each of the load cell, preventing it from being affected by non-vertical forces and ensuring repeatability of its signal output. The intellegent junction box joins the wires from the individual load cells and equalises the mV signals from the load cells to create an average mV value which is transmitted to the weight indicator or controller. Our indicators have several communication options to transmit the weight to a PLC or PC.

To create a complete weighing system Optima have extentive range of Weighing Inicators, Load Cells, Mounting Kits, Intellegent Junction Boxes, Weighing Assemblies, Weight Transmitters and accessories.

View our complete range of Silo/Tank/Hopper/Vessel Weighing Systems in the following selection guide OR

Contact Us to talk with technical experts or to get a quick quotation now.

Download our catalogues or read Applications.

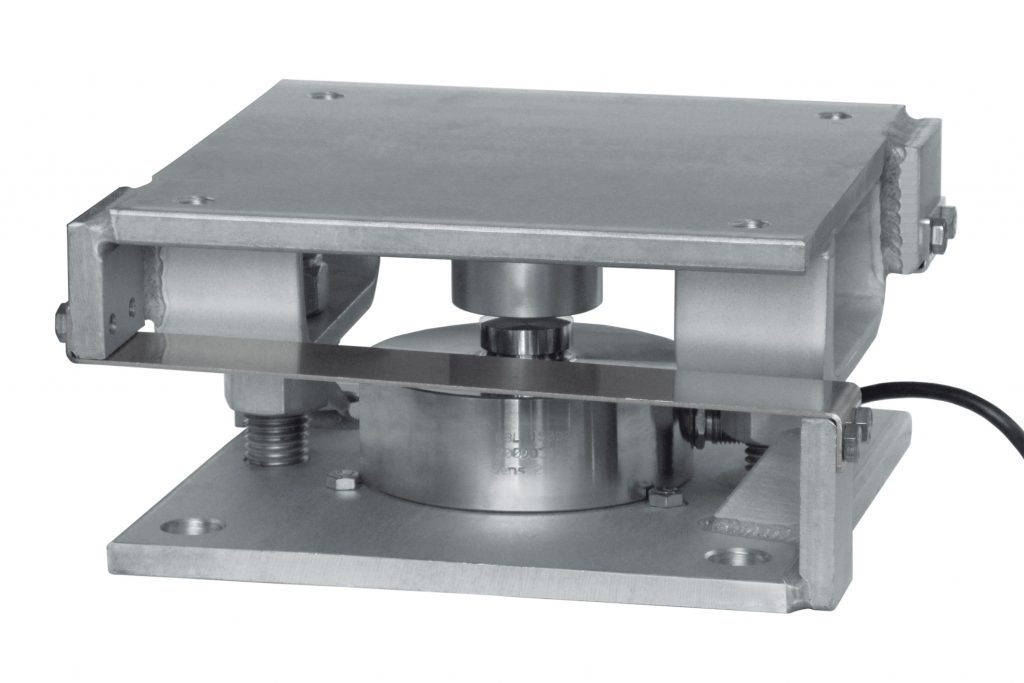

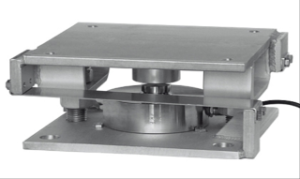

Compression Load Cell With "V" Range Weighing Modules Up To 100000kg For Silo/ Tank/ Hopper/ Vessel Weighing

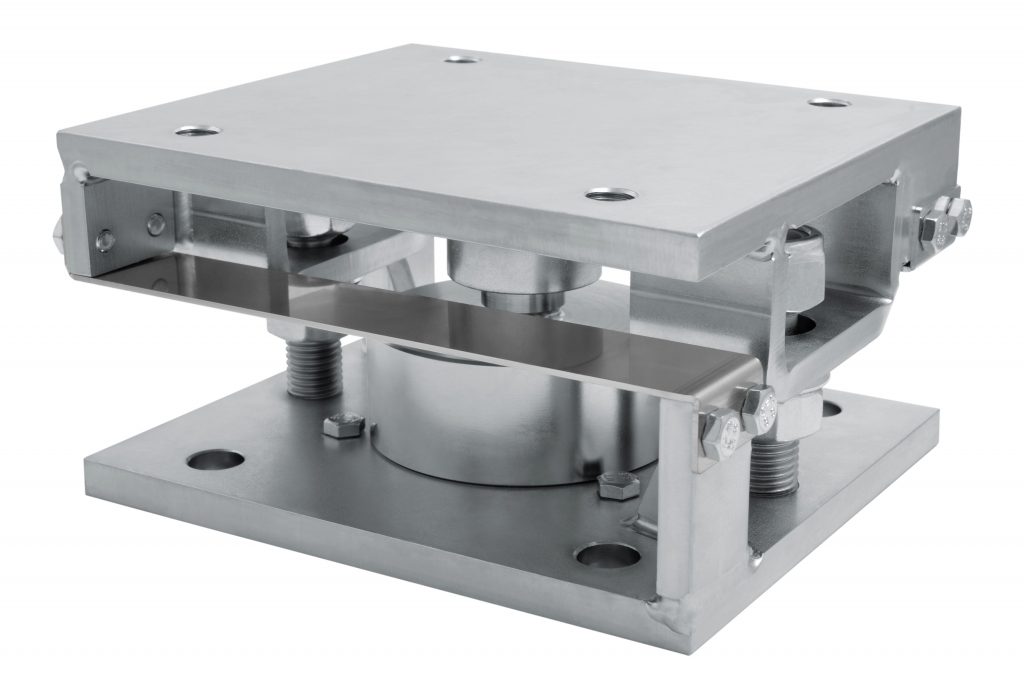

Compression Load Cell With "V" Range Weighing Modules Up To 50000kg For Silo/ Tank/ Hopper/ Vessel Weighing

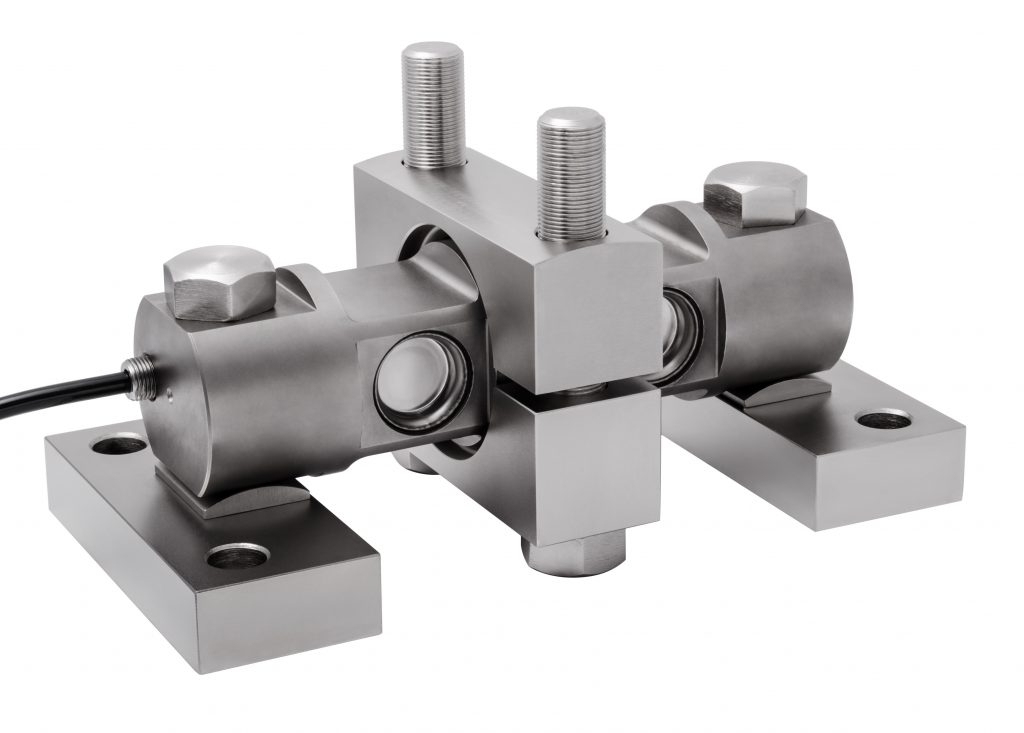

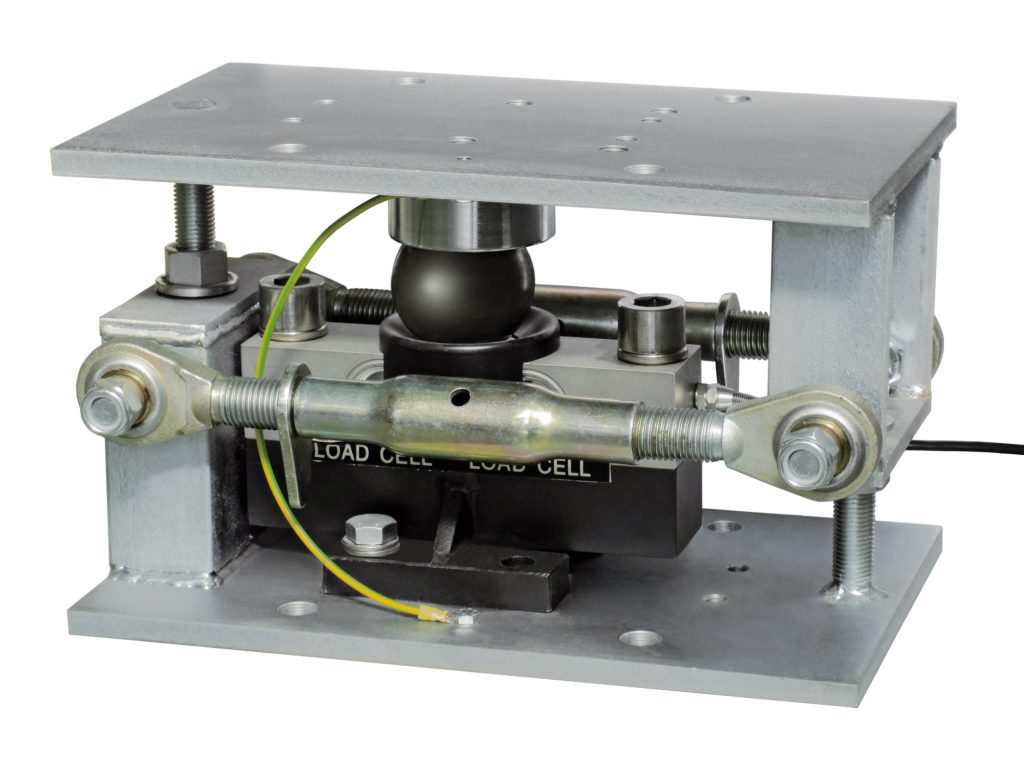

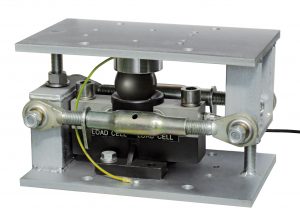

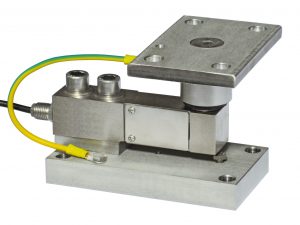

Double Ended Shear Beam Load Cell With VDTX Weighing Modules Up To 27000kg For Silo/ Tank/ Hopper/ Vessel Weighing

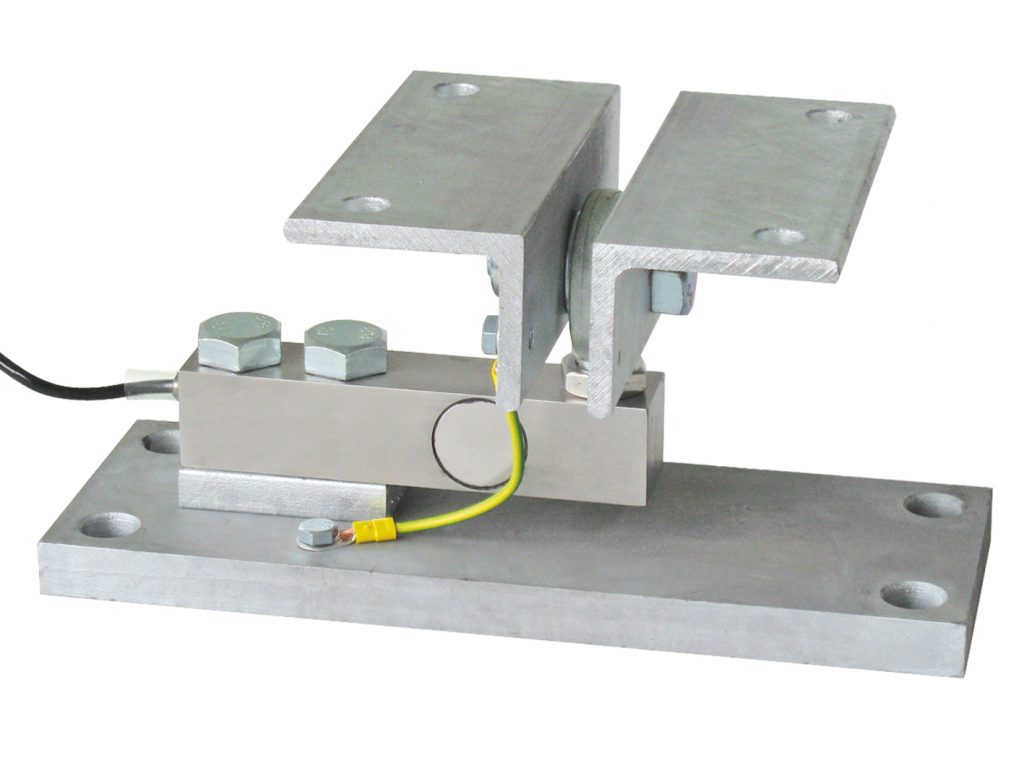

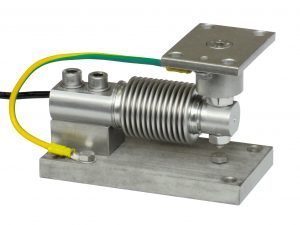

Single Ended Shear Beam Load Cell With PS Weighing Modules Up To 10000kg For Silo/ Tank/ Hopper/ Vessel Weighing

Compression Column Load Cell With VCOKDTL Weighing Modules Up To 60000kg For Silo/ Tank/ Hopper/ Vessel Weighing

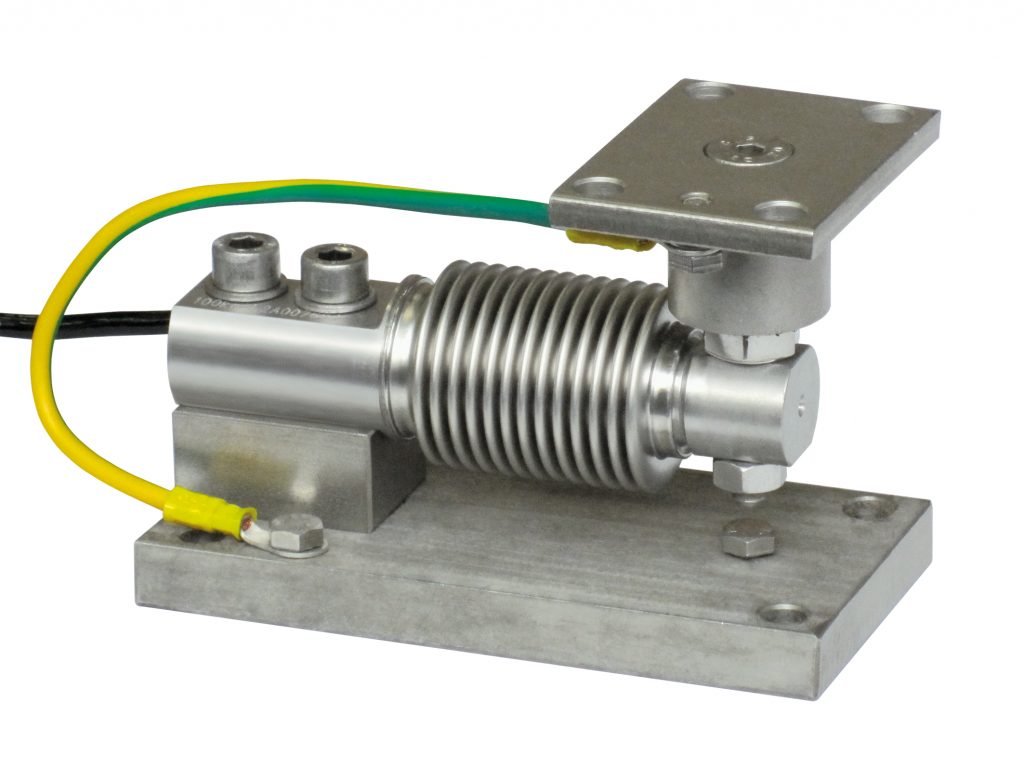

Bending Beam Load Cell Mounting Kit For Tank/Hopper/Silo/Vessel from 5 to 500 kg

Shear Beam Load Cell Mounting Kit For Tank/Hopper/Silo/Vessel Up to 2000Kg

Load Cells For Tank Foots Up To 20,000Kg

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

“W” Series Weighing Indicators/Controllers For Display, Communications with PLC

CLM 8 Series Digital Equilization/Summation Weighing Transmitters

Optima has specifically supplied a range of OIML and NTEP approved load cells, weighing assemblies and instrumentation/electronics for accurate measurement during storage, loading or unloading of bulk solids and liquids. Please contact us to talk with experts and find out the suitable solution to your applications.

Ask Us A Question about our Silo/Tank/Hopper Weighing Systems

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

“W” Series Weighing Indicators/Controllers For Display, Communications with PLC

CLM 8 Series Digital Equilization/Summation Weighing Transmitters

Optima has specifically supplied a range of OIML and NTEP approved load cells, weighing assemblies and instrumentation/electronics for accurate measurement during storage, loading or unloading of bulk solids and liquids. Please contact us to talk with experts and find out suitable solution to your applications.

Ask Us A Question about our Silo/Tank/Hopper Weighing Systems

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

“W” Series Weighing Indicators/Controllers For Display, Communications with PLC

CLM 8 Series Digital Equilization/Summation Weighing Transmitters

Optima has specifically supplied a range of OIML and NTEP approved load cells, weighing assemblies and instrumentation/electronics for accurate measurement during storage, loading or unloading of bulk solids and liquids. Please contact us to talk with experts and find out suitable solution to your applications.

Ask Us A Question about our Silo/Tank/Hopper Weighing Systems

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

“W” Series Weighing Indicators/Controllers For Display, Communications with PLC

CLM 8 Series Digital Equilization/Summation Weighing Transmitters

Optima has specifically supplied a range of OIML and NTEP approved load cells, weighing assemblies and instrumentation/electronics for accurate measurement during storage, loading or unloading of bulk solids and liquids. Please contact us to talk with experts and find out the suitable solution to your applications.

Ask Us A Question about our Silo/Tank/Hopper Weighing Systems

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

“W” Series Weighing Indicators/Controllers For Display, Communications with PLC

CLM 8 Series Digital Equilization/Summation Weighing Transmitters

Optima has specifically supplied a range of OIML and NTEP approved load cells, weighing assemblies and instrumentation/electronics for accurate measurement during storage, loading or unloading of bulk solids and liquids. Please contact us to talk with experts and find out suitable solution to your applications.

Ask Us A Question about our Silo/Tank/Hopper Weighing Systems

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

“W” Series Weighing Indicators/Controllers For Display, Communications with PLC

CLM 8 Series Digital Equilization/Summation Weighing Transmitters

Optima has specifically supplied a range of OIML and NTEP approved load cells, weighing assemblies and instrumentation/electronics for accurate measurement during storage, loading or unloading of bulk solids and liquids. Please contact us to talk with experts and find out suitable solution to your applications.

Ask Us A Question about our Silo/Tank/Hopper Weighing Systems

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

“W” Series Weighing Indicators/Controllers For Display, Communications with PLC

CLM 8 Series Digital Equilization/Summation Weighing Transmitters

Optima has specifically supplied a range of OIML and NTEP approved load cells, weighing assemblies and instrumentation/electronics for accurate measurement during storage, loading or unloading of bulk solids and liquids. Please contact us to talk with experts and find out suitable solution to your applications.

Ask Us A Question about our Silo/Tank/Hopper Weighing Systems

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

We are here to help!

Our team has exceptional technical knowledge to quickly assist you!

“W” Series Weighing Indicators/Controllers For Display, Communications with PLC

CLM 8 Series Digital Equilization/Summation Weighing Transmitters

Optima has specifically supplied a range of OIML and NTEP approved load cells, weighing assemblies and instrumentation/electronics for accurate measurement during storage, loading or unloading of bulk solids and liquids. Please contact us to talk with experts and find out suitable solution to your applications.

Ask Us A Question about our Silo/Tank/Hopper Weighing Systems

| Model | # | |||

|---|---|---|---|---|

| Enquiry |

"Thank you Optima for your wonderful service. Your offered load cells and weight transmitters are helping in our research currently and we are impressed with your products specifications."

The University of Queensland

"Excellent service and knowledge provided. We needed a solution for our liquid packaging and Optima provided the best possible solution. The system is working fine and results are satisfactory. "

Real Foods

"Sandeep, you asked me if you are happy with your service. Let me tell you that Optima had quoted and delivered the product via air freight from Germany before other suppliers returned our call. Outstanding!"

Have a project in mind or just want to say hello? We’d love to hear from you! Contact us today and let’s start your journey!